Plastic Pet/PP/HDPE/LDPE/LLDPE/ABS/PS/PVC/PC/BOPP Bottle/Film/Bag/Drum/Pallet/Pipe/Container/Box/Jar/Barrel Washing Line Crushing Plant Recycling Machine

Overview Package size per unit product 8200.00cm * 600.00cm * 500.00cm Gross weight per unit product 26000.000kg Plastic

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | TPWL300~3000 |

| After-sales Service | Longlife After Service |

| Warranty | 12 Months |

| Material Processed | Plastic Bottle |

| Plastic Type | PET |

| Screw | Crusher&Shredder |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| Color | Could Be Customized |

| After-Sale Service | Eers Available to Service Machinery Overseas |

| Material of Recycling Machines | Stainless Steel |

| Electric Grid | 3p 220V~440V 50 or 60Hz |

| Transport Package | Wrap Film |

| Specification | TSWL300~3000 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 300~3000kg/H |

Packaging & Delivery

Package size per unit product 8200.00cm * 600.00cm * 500.00cm Gross weight per unit product 26000.000kgProduct Description

Plastic Pet PP HDPE LDPE LLDPE ABS PS PVC PC BOPP Bottle Film Bag Drum Pallet Pipe Container Box Jar Barrel Washing Line Crushing Plant Recycling MachineProduct Description

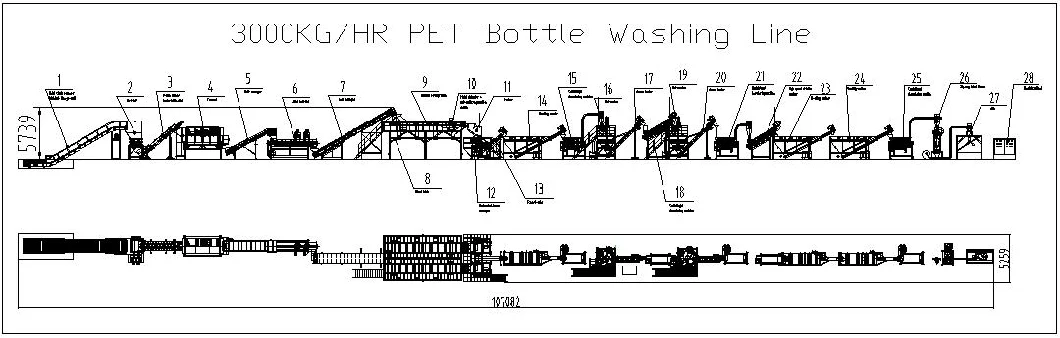

Our PET bottle washing recycling line is specially design to deal with waste PET bottles, such mineral water bottle, beverage bottles... the main function of our PET bottle recycling line usually include as below.(1) First to crush and wash the PET flakes finally get clean flakes.(2) Second to remove the labels thoroughly, third to remove the bottles caps fourth to dry the PET flakes, finally to get clean, pure and dry PET flakes. Combining wet crusher, friction washer, high speed friction washer floating washer and hot washer to guarantee the finally flakes good quality.(3) Our PET bottle washing production line is with high automatically operation and labor savings features.(4) With advanced design concept and constantly advises from customers, we can customized to meet all your specially demands.(5) This PET bottle crushing washing recycling line could be installed as "I", "L", and "U" shapes according to your workshop space. We also could help you to design how to install the machines in your factory.

Detailed Photos

Product Parameters

PET Flakes Quality Reference:

| Mousiture | <1% | Label | <30PPM |

| PVC | <50PPM | Variegated | <20PPM |

| Glue | <10PPM | PH | Neutral |

| PP&PE | <20PPM | Toal Impurity | <150PPM |

| Metal | <20PPM | Flake Size | Optional |

Estimated Plant Space of PET Bottle Washing Plant:

| Capacity (kg/h) | Power(kw/h) | Area(m*2) | Labor |

| 500 | 220 | 400 | 6 |

| 1000 | 500 | 750 | 8 |

| 2000 | 700 | 1000 | 10 |

| 3000 | 900 | 1500 | 12 |

Certifications

Packaging & Shipping

Solution

FAQ

1. What is the function of PET bottle washing recycling plant?

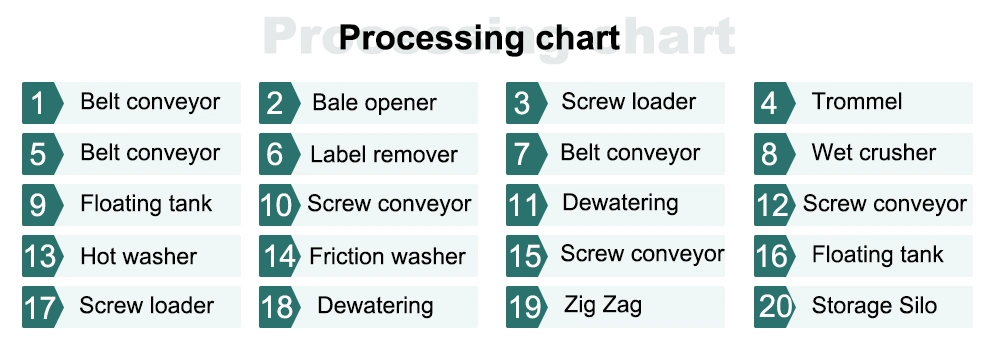

The PET bottle washing recycling plant is mainly used to process PET beverage bottles. The line includes two functions, one function is to separate the PE caps and PVC or PP caps out to get pure PET flakes finally. The other one function is to wash the PET flakes clean, at end to get clean flakes. 2. What are main parts of the PET bottle washing recycling plant?The PET bottle washing recycling plant is mainly consists of:Belt conveyer--- bale opener--- belt conveyer-pre-washer--- belt conveyer--- mechanical label separator--- manual sorting--- metal detector--- belt conveyer--- crusher--- screw conveyer--- floating washer--- screw conveyer--- hot washer--- screw conveyer--- high speed friction washer--- screw conveyer--- floating washer--- screw conveyer--- vertical dewatering machine--- drying system--- zigzag label separator--- storage silo--- operating panelThe up structure of the flowing chart is just a standard we recommend, it can be adjusted due to the customers' material situation and requirements. 3. What capacity of the PET bottle washing recycling plant?300-3000kg/h for single washing line4. What power of the PET bottle washing recycling plant?150kw~350kw 5. How much water does it need of the PET bottle washing recycling plant?3~8T per hour 6. How large space does it need for a PET bottle washing recycling plant?100~400 square meters 7. Do you offered training of the PET bottle washing recycling plant?Yes, we can training your worker. 8. Can you send engineers to our factory to help us install the PET bottle washing recycling plant?Surely it is no problem. 9. Do you offer all the documents for the PET bottle washing recycling plant? Such as the manual operating.Yes, we will offer you the complete documents for the PET bottle washing recycling plant. 10. What is the situation of the final products from the PET bottle washing recycling plant? The PET flakes from the PET bottle washing recycling plant moisture level lower than 1%, the PVC level lower than 200PPM, the dirties level lower than 300PPM.11. What certifications do you have for the PET bottle washing recycling plant?We have CE and ISO9001 certification for the entire PET bottle washing recycling plant. 12. What is material of the PET bottle washing recycling plant?The parts contacted with water are made of stainless steel SUS 304 for the entire PET bottle washing recycling plant.13. Does it easier and costly to maintenance for the PET bottle washing recycling plant. It is easier and not costly. We will train your workers and offer the manual operating. 14. What about the electrics of the PET bottle washing recycling plant?Our standard electric parts are famous brand, such as Siemens Contactor, Fuji inverter… and also they are customized for the PET bottle washing recycling plant.15 workers needed for the PET bottle washing recycling plant?4-12 people

plasticmachine.en.made-in-china.com

Exhibition

Related Products

-

![Automatic Anti-Corroisve Bottle Toilet Cleaner Oblique Neck Bottle Liquid Filling Packing Machine]()

Automatic Anti-Corroisve Bottle Toilet Cleaner Oblique Neck Bottle Liquid Filling Packing Machine

-

![Automatic Eyelet Grommet Punching Setting Fixing Attaching Machine No Washer Version]()

Automatic Eyelet Grommet Punching Setting Fixing Attaching Machine No Washer Version

-

![Aluminium Rivets with Best Quality, Round and Flat Head Aluminium/Steel Open-End Blind Rivet]()

Aluminium Rivets with Best Quality, Round and Flat Head Aluminium/Steel Open-End Blind Rivet

-

![CMM CNC Milling Cylinder Boring Drilling Metal Lathe Grinder Machine Tools Accessories Part Center Holder Infrared Optical Radio Transmission Touch Probe]()

CMM CNC Milling Cylinder Boring Drilling Metal Lathe Grinder Machine Tools Accessories Part Center Holder Infrared Optical Radio Transmission Touch Probe