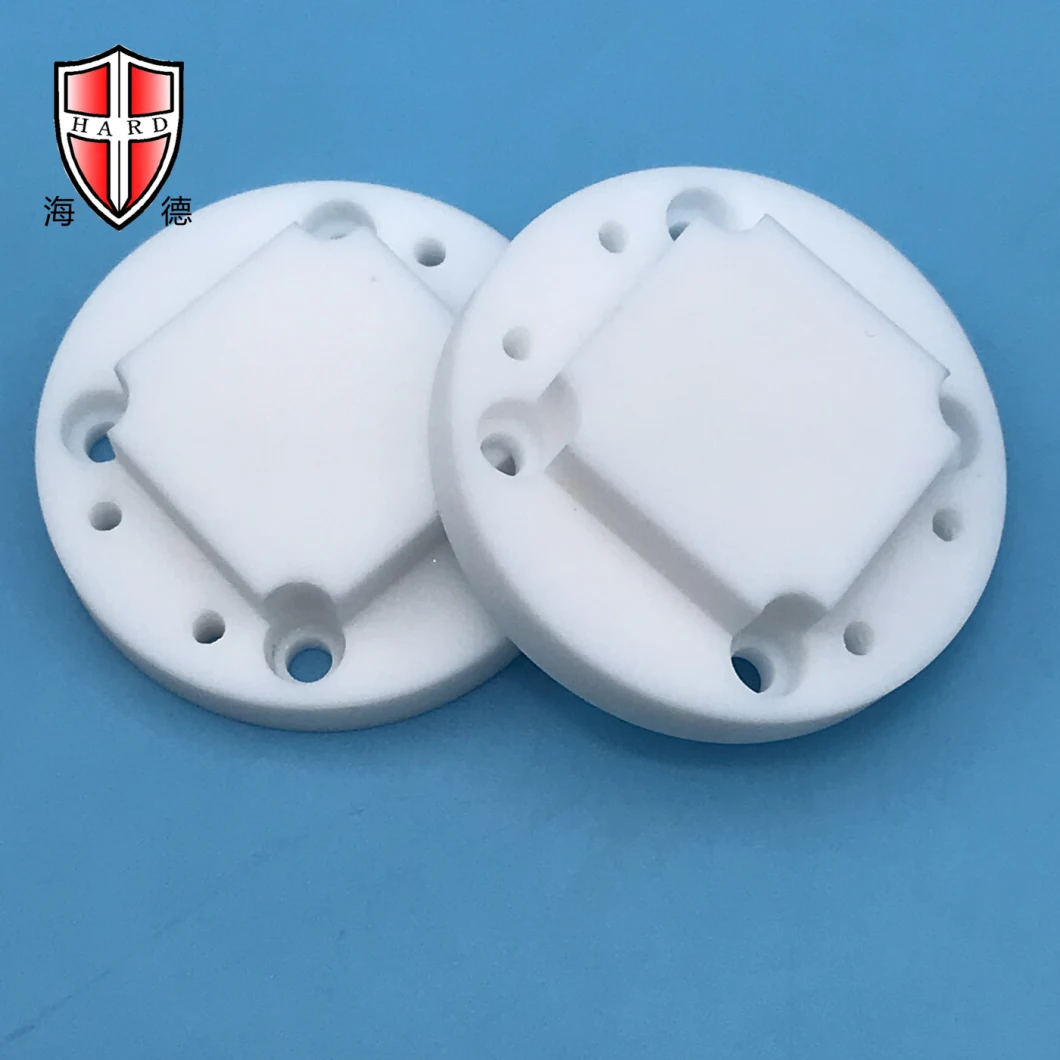

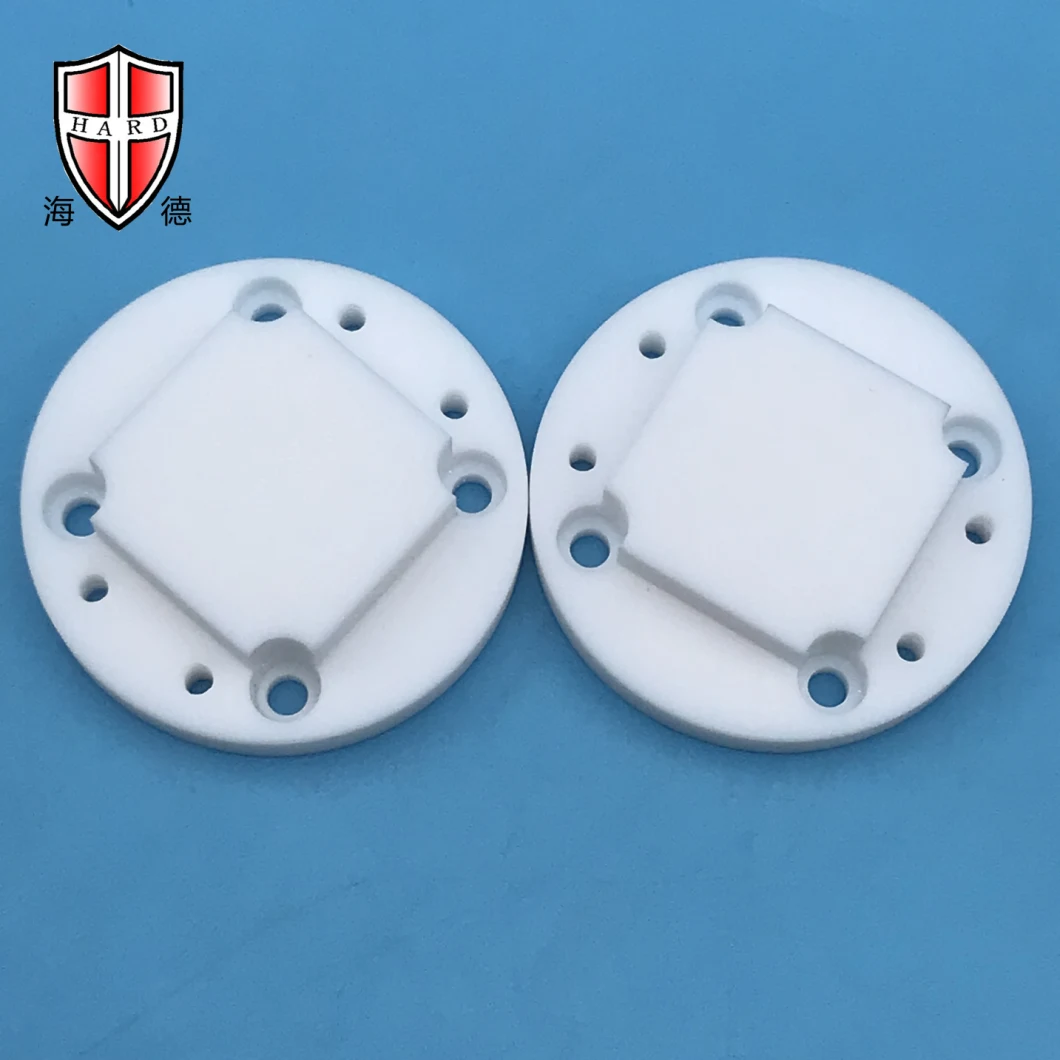

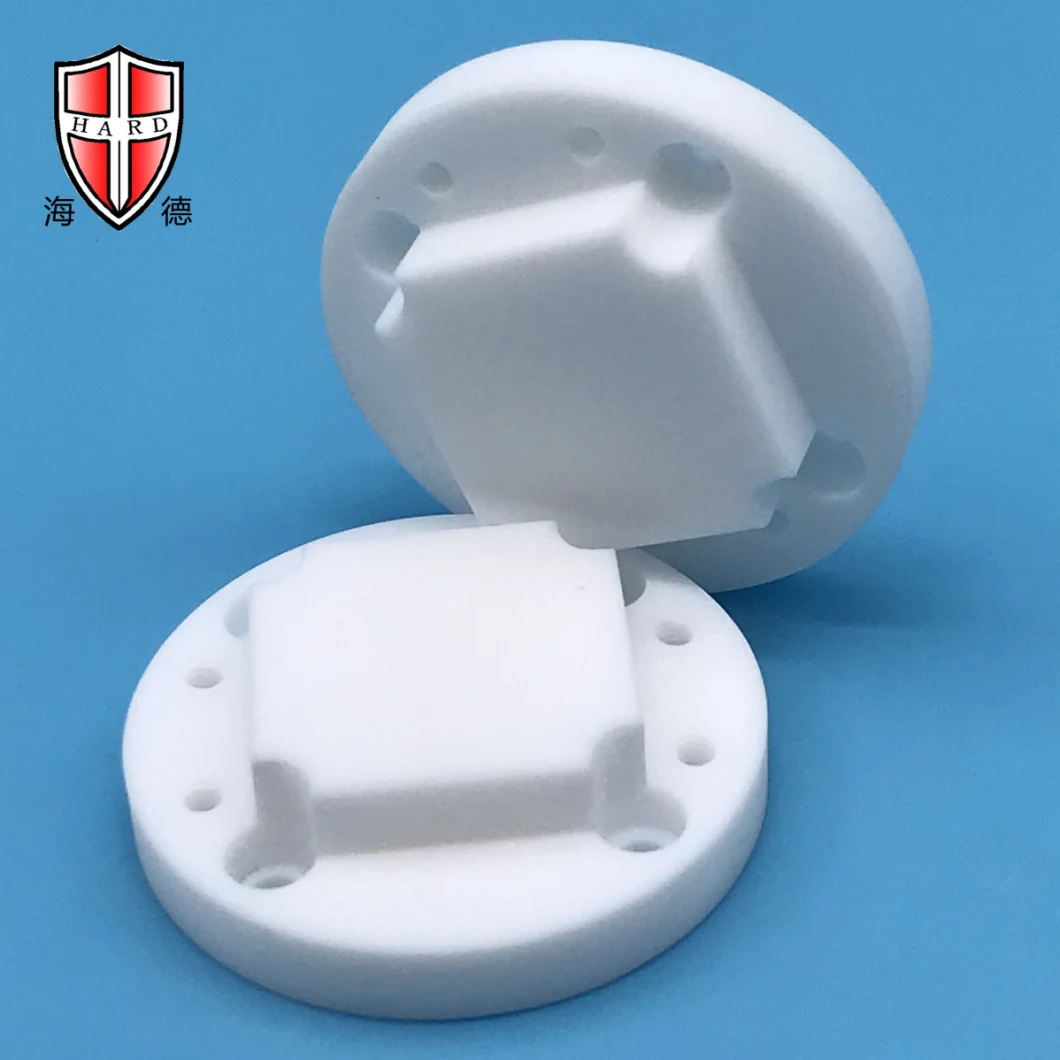

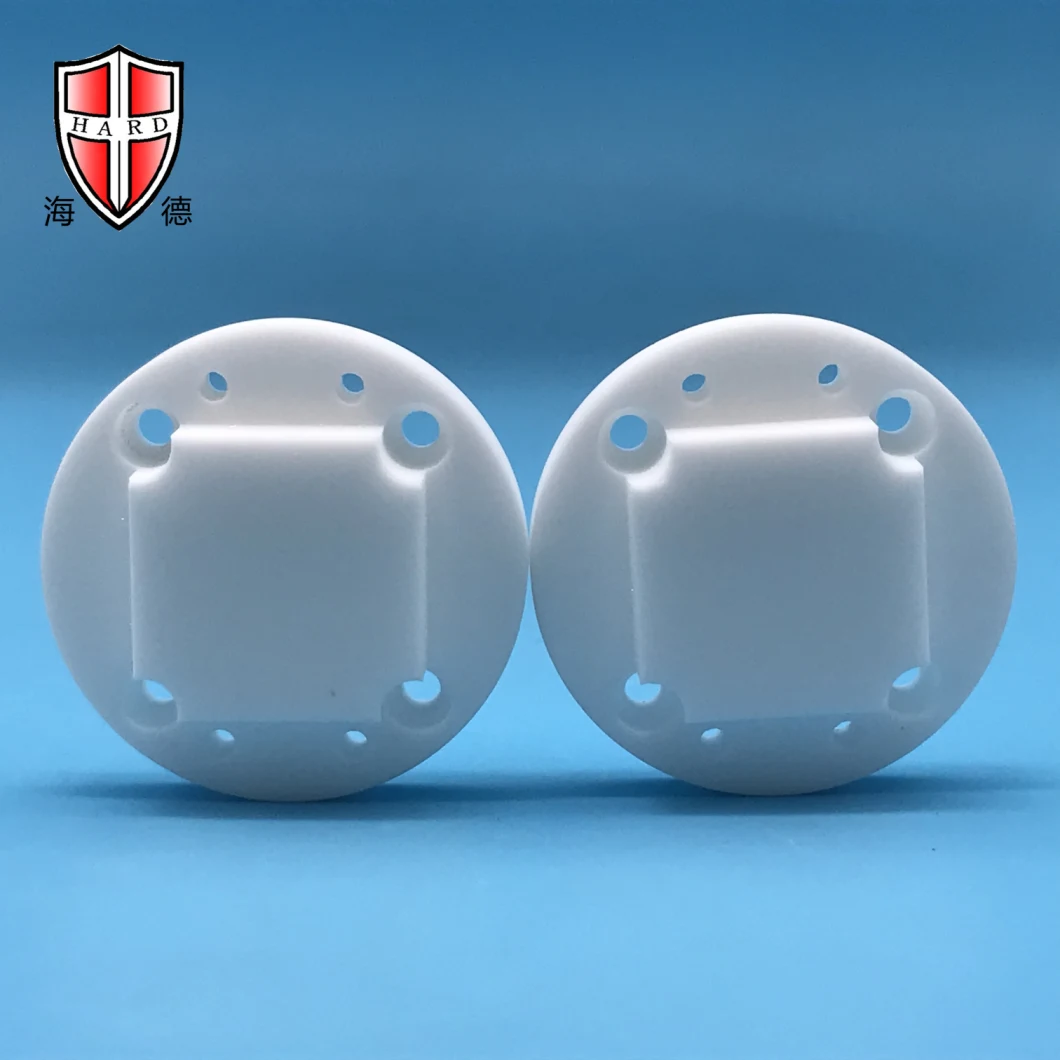

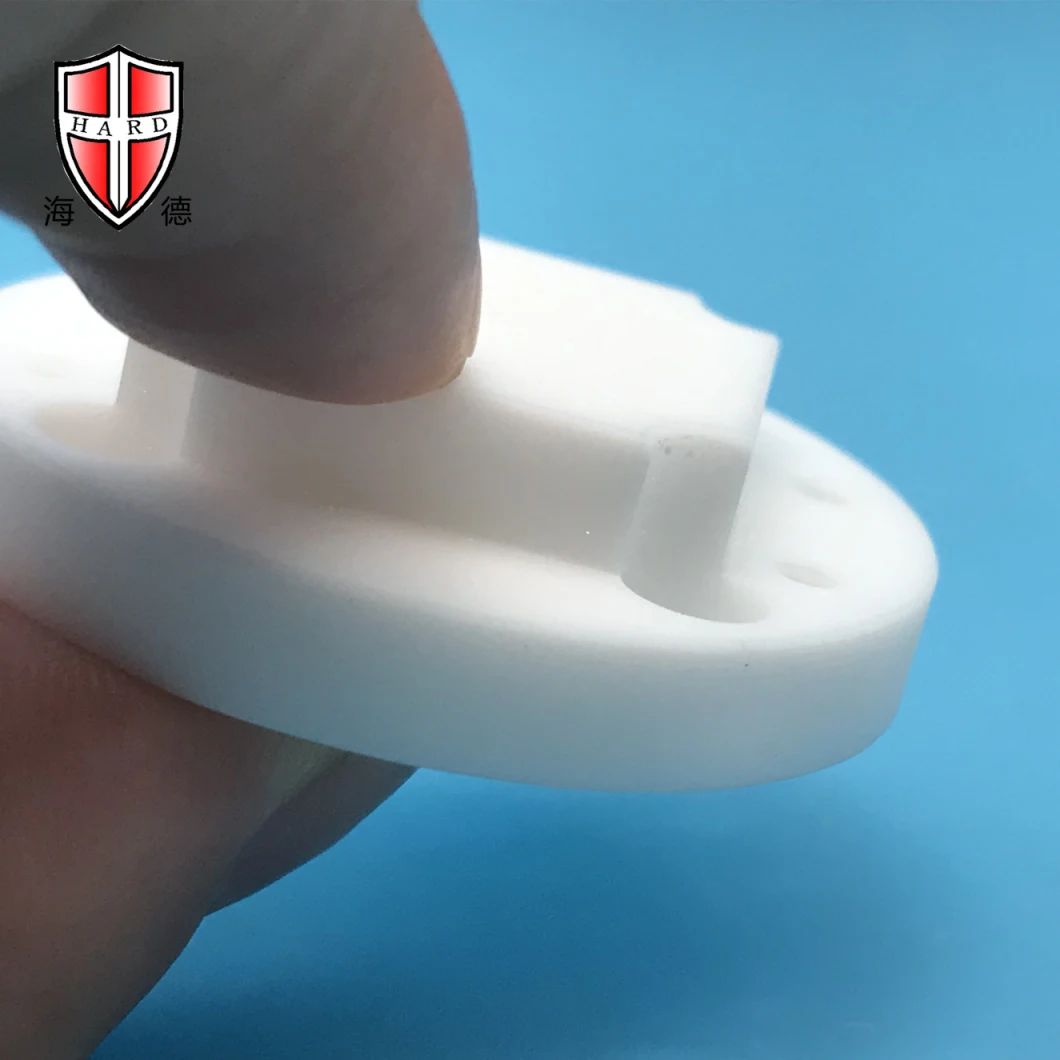

Ceramics Custom Made High Temperature Insulating Parts of Mechanical Equipment Mica Macor Ceramic Eyelet Plate Disc

Ceramics Custom Made High Temperature Insulating Parts of Mechanical Equipment Mica Macor Ceramic Eyelet Plate Disc Mica

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Macor 085 |

| Application | Ceramic Decorations, Refractory, Structure Ceramic, Industrial Ceramic, Machinery, Electronic, Chemical, Petroleum etc. |

| Material | Macor Machinable Ceramic |

| Type | Ceramic Parts |

| Color | White |

| Density | 2.6g/cm3 |

| Gas Permeability | 0 |

| Water Absorption | 0 |

| Weight | Customized |

| OEM/ODM | Available |

| Maximum Use Temperature | 800c |

| Flexural Strength(20°c) | 108 Gpa |

| Compressive Strength(20°c) | 488 Gpa |

| Lead Time | 10 Days |

| Transport Package | Box/Carton / Plastic Bag / Wooden Case… |

| Specification | Customized |

| Trademark | Hard |

| Origin | Shenzhen, China |

| HS Code | 6903200000 |

| Production Capacity | 10, 000, 000PCS/Month |

Product Description

Ceramics Custom Made High Temperature Insulating Parts of Mechanical Equipment Mica Macor Ceramic Eyelet Plate DiscMica Glass Ceramic:

Microcrystalline glass ceramics, also known as machinable ceramics, are mica glass-ceramics with synthetic mica as the main crystalline phase, and are ceramic materials that can be machined. Microcrystalline glass ceramics have excellent processing properties, vacuum properties, electrical insulation properties, and high temperature and chemical resistance. Glass-ceramics have high mechanical strength of glass-ceramics, machinable glass-ceramics and bioactive glass-ceramics.Machinable ceramics refer to ceramic materials that can be drilled, turned, milled, etc. with tools and instruments for metal processing.

Mica Glass properties:Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Density | g/cm3 | 2.6 |

| Gas permeability | 0 | |

| Water Absorption | 0 | |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 40 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm²) | 11.5(1175) |

| Flexural Strength(20°C) | Mpa | 108 |

| Compressive Strength(20°C) | Mpa | 488 |

| Modulus of Elasticity(25°C) | Gpa | 65 |

| Thermal Properties | ||

| Thermal Conductivity(25°C) | W(m.K) | 1.71 |

| Thermal Expansion Coefficient | 10-6/°C | 7.2 |

| Thermal Shock Resistance | △T°C | 200 |

| Maximum Use Temperature | °C | 800 |

| Electronic Properties | ||

| Dielectric Strength | KV/mm | >30 |

| Volume Resistivity(20°C) | Ω.cm | >10(16) |

Application industry: Machinery, electronic, limitary, aerospace etc.

Specific application: Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

Specific application: Microcrystalline glass ceramics are particularly suitable for automotive, military, aerospace, precision instruments, medical equipment, electric vacuum devices, electron beam exposure machines, textile machinery, sensors, mass spectrometers and energy spectrometers. For some thin-walled coil bobbins, precision instruments, insulated brackets, and high-precision devices with high precision requirements, glass-ceramics are more suitable, and they can be processed into any shape.

Company Information

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, molding, sintering, production and sales of precision ceramic products. After 10 years of development, we have cooperated with more than 2000 customers and 60 universities; Our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.Our products include ceramic rods, tubes, plates, blocks and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. Hope for a wide range of sincere cooperation with customers at home and abroad.

Why Choose Us?

1.12 years of professional production industrial ceramics factory2.High quality products with low price3.High precision parts with lowest tolerance4.Show time for production 5.Has a group of experienced, professional and efficient R&D team6.Has a good reputation in China and abroad.7.MOQ is not limited, small quantity is welcome.8.Vigorous team and good after-sales service

Product ShowFactory ShowPackaging & ShippingOur TeamFAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Contact Us

Related Products

-

![Rivet Nut M6 SS304 Half Hex External Hex Internal Hex]()

Rivet Nut M6 SS304 Half Hex External Hex Internal Hex

-

![Gl206 Plastic Injection Auto Parts Fastener Christmas Tree Rivet Barbed Buckle for Fixing Automobile Interior]()

Gl206 Plastic Injection Auto Parts Fastener Christmas Tree Rivet Barbed Buckle for Fixing Automobile Interior

-

![CMM CNC Milling Cylinder Boring Drilling Metal Lathe Grinder Machine Tools Accessories Part Center Holder Infrared Optical Radio Transmission Touch Probe]()

CMM CNC Milling Cylinder Boring Drilling Metal Lathe Grinder Machine Tools Accessories Part Center Holder Infrared Optical Radio Transmission Touch Probe

-

![Strap Adjuster Underwear Accessories Bra O Rings and Sliders]()

Strap Adjuster Underwear Accessories Bra O Rings and Sliders